MEGA MIX Operation

MEGA MIX is the most innovative cost efficient use of materials available to deliver, dry store, and consistently produce quality on site products meeting all ASTM, architectural, and engineering standards while substantially increasing productivity, eliminating landfill waste and providing a safer, cleaner job site.

*Mortars *Architectural Concrete *DryPack

*Stucco *Blended Cements

*Grout *Custom Colors

*Mortars *Architectural Concrete *DryPack

*Stucco *Blended Cements

*Grout *Custom Colors

|

Credits LEED’s to Points

* 20% Recycled Product 2 points * 100% Local Product 1 point *100% Elimination of Landfill Waste 2 points |

Innovative Technological Construction Performance Strategies Adds Credits

*Dry Storage *Light Pollution Reduction *EPA/NPDES Conformance *Health and Safety *Organized Construction Site |

Specifications

Weight empty: 2.9 tons-6,000 lbs

Weight full: 23 tons- 46,000lbs

Max. mortar capacity: 14.2 cu. yards

Overall height: 20 feet

Overall width: 8 feet

Electrical requirements: 220 Volt single phase (4 wire)

Weight full: 23 tons- 46,000lbs

Max. mortar capacity: 14.2 cu. yards

Overall height: 20 feet

Overall width: 8 feet

Electrical requirements: 220 Volt single phase (4 wire)

MEGA MIX mortar from the patented two compartment silo will meet or surpass all construction specifications

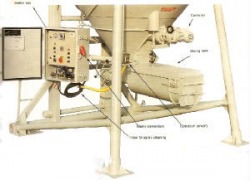

Silos Deliver and Produce Cost effective Products

Mega Mixers contain specified materials for a project that can automatically dispense thoroughly mixed products meeting ASTM specifications. Contractors are adapting to this method of producing mortars and stucco on job sites for many reasons. Of major importance are the ease and speed at which the machines continuously mix on demand and the superior consistency and quality of the mix. Fully automated silos provide substantial labor savings over conventional means of shoveling sand and breaking bags into mixers. Mega Mixers resolves the difficulties of material handling; materials are now delivered from one supplier, stored and mixed within the silo. The company is able to provide an array of popular cements and aggregates, including custom colors and almost any custom blend of special cements. Products are backed with a quality control program to assure the design of mixes are met and that customers are properly trained to operate the equipment.

Big Advantages!

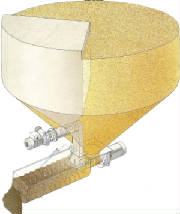

- Two compartment silo with electronic variable speed ratio controls. Volume ratio 3:1 (sand to cement)

- Accurately produces a controlled product from job start to completion. Produces mortar and stucco products meeting ASTM C270 for unit masonry and C926 for stucco plaster.

- Automated blending apparatus and patented high intensity mixing chamber increases job site productivity.

- Waste and theft is eliminated and no left over materials at job site.

- The contractor pays only for the materials used. Silos are weighed at delivery and at return.

- Superior color mortar production.

- Also excellent for one coat stucco, fibered stucco, grout and other special blends.

- Volumetric material controls permit user to specify type and quality of stucco or mortar.

- Uses damp or dried stucco sand, masonry sand, and concrete sands with 3/8’’ aggregates.

GREEN, CLEAN MACHINES ADDS CREDITS TO YOUR PROJECTS

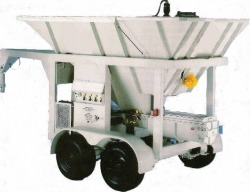

Jr. Mix Operation

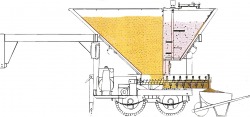

Jr. Mix is a portable, self-contained, material mixing and delivery unit. Jr. Mix offers customers the ability to move product around job-sites with no material handling, and eliminating piles of sand and cement. This reduces costs, waste and cleanup time. You can expect quality and a consistently mixed product with this versatile delivery-mixing unit. Mixer controls are set at delivery to meet engineering specifications. Water can be adjusted to satisfy applicators workability needs at the site. Jr. Mix's design protects material from contamination and loss from handling bags, theft and weather.

Portability, Lower material handling costs, Consistently mixed product

The new Jr. Mix rapidly dispenses dry pack, cement and sand, thoroughly mixed for use to build up and level floors or create slopes where required.This easily portable equipment substantially increases productivity and reduces labor. It comes in three sizes, 5 yard, 3 yard, and 1 yard, to suit various contractors and towing capabilities. Contractors can fill equipment at any supply yard or at the job site with their choice of sand and cement. Job site operator’s can add liquid or dry admixtures for waterproofing and mold resistance along with fibers for added strength. Adjustable ratio controls produce a consistent finely mixed product meeting project specifications. Jr. Mix fills a wheel barrow in one minute or a mud tub in 4-5 minutes. Use of equipment also gains points towards LEED certification for sustainable Green Building Rating System and can reduce workmans compensation modification factor.

Easy to Operate

The new Jr. Mix rapidly dispenses dry pack, cement and sand, thoroughly mixed for use to build up and level floors or create slopes where required.This easily portable equipment substantially increases productivity and reduces labor. It comes in three sizes, 5 yard, 3 yard, and 1 yard, to suit various contractors and towing capabilities. Contractors can fill equipment at any supply yard or at the job site with their choice of sand and cement. Job site operator’s can add liquid or dry admixtures for waterproofing and mold resistance along with fibers for added strength. Adjustable ratio controls produce a consistent finely mixed product meeting project specifications. Jr. Mix fills a wheel barrow in one minute or a mud tub in 4-5 minutes. Use of equipment also gains points towards LEED certification for sustainable Green Building Rating System and can reduce workman's compensation modification factor.

Specifications

Weight empty: 9,280 lbs

Weight full: 25,280 lbs

Capacity: 5.3 cu. yards

Overall height: 10.75 feet

Overall width: 8.5 feet

Overall length: 19.5 feet

Weight full: 25,280 lbs

Capacity: 5.3 cu. yards

Overall height: 10.75 feet

Overall width: 8.5 feet

Overall length: 19.5 feet

- Diesel powered

- Hydraulically operated

- Variable speed

- Tandem axles with electric brakes lights on trailer

- Fifth wheel trailer hitch.

Big Advantages

*Sand-cementitious material ratios preset to job specifications before delivery

*Continuous quality control from startup to completion

*Sealed product compartments prevent material contamination and loss due to theft or weather

*Reduces startup labor in the morning and jobsite cleanup at night

*Portability allows leftover material to be taken to next job

*Diesel operated; no electric power required

*Environmentally safe

*Winter water heating engine exhaust system available as an option

*Continuous quality control from startup to completion

*Sealed product compartments prevent material contamination and loss due to theft or weather

*Reduces startup labor in the morning and jobsite cleanup at night

*Portability allows leftover material to be taken to next job

*Diesel operated; no electric power required

*Environmentally safe

*Winter water heating engine exhaust system available as an option